Welcome

DetNet database

The DetNet database includes ca. 200 formulations ('Reference Formulations'), covering a wide range of market relevant mixtures, each supported by skin and/or eye toxicological test data, either historical in vivo or recently generated data using in vitro methods. The database will constantly be enriched and updated based on members’ input and latest industry research.

The DetNet database provides a Reference Formulation Search Tool which allows identifying potential reference formulations for further evaluation. The reference formulations include laundry detergents (liquids and powders), hand dish wash detergents and all-purpose cleaners. For each reference formulation the compositional details, the physical-chemical data and the toxicological summary of associated test data are available. Reference Formulation compositions are made available to experts from companies using a fixed format that provides sufficient detail to enable comparison of mixtures and application of bridging principles, but still protects confidential business information of the data owner (e.g. no trade name of ingredient, use ‘perfume’ generically, etc.)

Toxicological data of Reference Formulations include new in vitro data (generated using validated in vitro test methods, such as the EpiSkinTM Skin Irritation Test, and the Isolated Chicken Eye Test enhanced with histopathological assessment - for more information on the ICE test and histopathology, click here), as well as historical in vivo studies. All studies have been assessed for quality and reliability (Klimisch scoring) and study summaries are available for each test report.

A.I.S.E. expects the database to grow over time, as more in vitro data are generated and new products types are added.

Experts

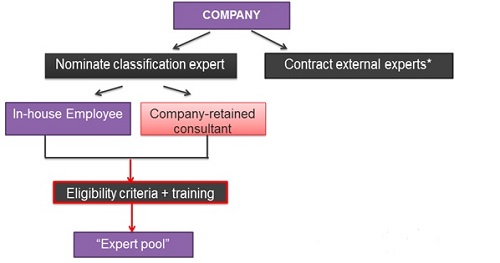

The DetNet database can be used by the classification expert(s) nominated by the company or by one of the external experts (as shown in the diagram below):

The classification expert appointed by a company can be:

- A company employee (in-house expert) or

- A consultant contracted by the company to carry out classification assessments.

The classification expert(s) has to be nominated by the company once it has filled in the DetNet user agreement. For more details about the nomination process click here.

The role of the expert (in-house, contracted or external) is to:

- Undertake training prior to the use of the DetNet database and demonstrate competency in application of the classification approach;

- Use the classification explanatory notes developed by A.I.S.E. to classify detergent and cleaning products for skin and eye irritation/corrosion;

- Compare the composition of the untested mixture to the reference formulations included in DetNet database and select the most appropriate ones for classification purposes, as applicable;

- Complete the agreed level of documentation to support classification decisions;

- Refer issues, inadequacies or problems with the guidance and gaps in the DetNet database to the DetNet manager;

- Discuss and explain classification decisions with national authorities when required - such issues are to be notified to DetNet manager which will provide support as necessary.

For more information on experts click here.

Steps

In practice, a company and its nominated expert(s) will go through the following steps (roll your mouse over for details):

Step 1:

- Sign up to join and pay your subscription fees

- Nominate your classification expert(s)

Step 2:

- Get log in details and access the secure site

Step 3:

- Input mixture to be classified and search in the DetNet database

- System presents possible matching formulations

Step 4:

- Expert determines if it is possible to derive the classifications of the untested mixture by comparison with tested reference formulations and applying ‘CLP bridging principles’

Step 5:

- If can apply bridging principle(s), follow on-screen instructions to document your classification decision

- Download and store final classification record

Step 6:

- Label your mixture for skin and eye effects (other hazards may also be covered)

- Update your Safety Data Sheet (SDS) accordingly